Prepared on Notepad by

Ian Smith,

This page created on 12th July 1998, updated 22nd December 2001

Production buses, RM5-7, 9-879, 904-1253, 1255-1452, 1521-2217. (Total 2119)

This section is in several parts:

This section is in several parts:

- Appearance and Construction variations

- Into service

- The Trolleybus replacement programme

- Replacing the RT family

- Surviving OMO: 1965-1984

- Nationalisation

- Privatisation

- Survivors

- RM Conversions

- RM Resurrection: the Marshall Rebuilds

- Heritage Routemasters: Routes 9 and 15

- Photograpic References

- Fleet history

Twenty years of design advance? RM291 and RT191

Appearance

Outwardly, all the standard length production BUSES looked very similar.

The style adopted with RM8 was continued through production,

with just a few visual changes as time progressed,

mainly concerned with air grilles at the front of the vehicles:

- Front windows: were either fitted with quarter-drop openings, or not.

RM 5 - 253 had the non-opening windows at first, RM254 onwards had quarterdrops.

Some early buses were retro-fitted with quarterlights, but this was never done routinely.

The mix of bodies at overhaul later spread the early bodies through the number range.

- Upper Saloon vents: the early bodies, up to RM354 had air scoops above the fixed front windows

that fed air into the upper saloon through grilles in the front dome.

(So RM255-354 had both opening windows and air scoops).

- Heater vent grilles: the heating system took air through a large grille above the cab,

through a radiator, then into the saloons.

Between 1964 and 1980 RMs had the bottom half of the grille plated over

at overhaul. Some buses later had the top half covered as well.

RM 613 has quarter-drop windows,

and the remains of early air-scoops above them.

The brake vent and heater vent grilles have been restored on this show bus,

and the radiator is the newer pattern.

RM613 has been restored and maintained in immaculate condition by staff

at Stagecoach East London's Upton Park garage.

- Radiator grilles: the early production grille had an aluminium surround

with a central vertical red strip. There was an LT totem on the bonnet front.

From RM949 onwards this was replaced by a stainless steel surround

with a polished central strip.

In 1963 a number of Shepherds Bush buses were experimentally retro-fitted

with new grilles where the central bar had a red background

behind the stainless steel. The background flared at the top.

These were later fitted with V-shaped badges. The LT totem on the bonnet was removed.

RM1662 was fitted with the next generation,

where the grille incorporated the V-shaped badge,

although the stainless steel bar lacked the red rim of the Shepherds Bush trials.

This fitting went into production on RM1665, 1680 and 1682 onwards,

and was rapidly fitted throughout the fleet.

(Although some bonnet totems appeared above V-badges at times).

Preserved RM1000 is dressed as new: apart from the later pattern radiator

In later years some radiator grilles were replaced by the later RML style,

with the number plate below the grille rather than inset.

When the re-engining programme developed,

RMs usually lost their AEC-style V-badges, leaving an untidy gap at the top of the grille.

This was not disguised by the common practice of painting the grille surround red.

Now some companies are replacing the V-badges with new white-triangle ones.

-

Offside route number windows: appeared on RMs up to RM1742.

After this, new buses did not have them,

and they were painted over or re-panelled on existing buses

(It had been decided that they encouraged potential passengers

from the wrong side of the road,

who might get run over whilst dashing to catch the bus.)

-

Brake vent grilles: RM 5- RM1901 had air vents below the headlamps,

the prototypes having suffered from brake overheating problems.

However, experience with RM1254 and the re-vamped RMC 1469

showed that these were no longer needed.

The order went out to seal them up.

RM1902 (et seq) was delivered with a blanking plate in front of the mesh.

Replacement panels were fabricated in a plastic material,

without grille holes,

and gradually replaced the old metal panels.

RM 1599 (Stagecoach East London) and RM2033 (London United)

on duty at North Weald rally in June 1998.

Both have the later deeper style of front valances,

without brake vents,

alongside grilles with inset number plates.

RM1599 has a deep cream cant-rail band,

whilst RM2033 sports a white band.

Both have the lower part of the heater inlet grille blanked over,

with the cant-rail stripe painted over it.

The latter also flashes a set of polished nut rings.

-

ROUTEMASTER transfers above the fleet numbers had featured in the early days,

as LT worked to establish a strong brand-name for the bus.

These were discontinued from RM 2046.

-

The cream band was standard London Transport Livery for Central Buses until 1965.

RM 2128 was experimentally painted with a flake grey band instead,

and this became standard for production from RM 2210 onwards.

It was then applied to the rest of the fleet.

-

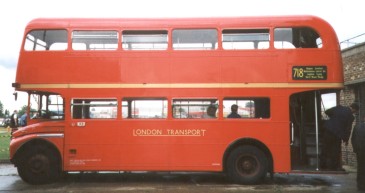

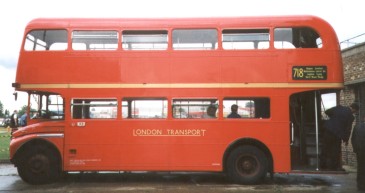

Fleet names RMs had the

LONDON TRANSPORT

fleetnames in black-edged gold, at first.

These began to be replaced by gold block-lettered LONDON TRANSPORT in 1969.

Stagecoach show-bus RM613 has the London Transport fleet-name

restored in the original form.

Gold fleet numbers and small "Routemaster" transfers have been re-applied too,

and the cant-rail band has been restored to cream.

In May 1970 a hundred RMs had their fleetnames replaced by white

open bullseyes, the nearside one under the second downstairs window,

and the offside one on the staircase panel.

From April 1974 solid white bullseyes were applied to all RMs

in place of the fleetname,

this time under the second window on both sides.

-

Fleet numbers changed from black-outlined gold to white in 1974 too.

-

Wheel trims were fitted to the rear wheels of new RMs,

and nut covers to the front wheels.

Apart from showbuses these were painted brown or maroon to match the wheels.

An instruction to remove the rear-wheel discs was issued in November 1971.

The change that this made to the appearance of the fleet was quite dramatic.

The front nut covers survived, but just now many operators seem to be deleting them.

Again, the RMs seem undressed without them.

RM 1840 shows a typical 1998 working condition:

wheel trims and nut covers have gone;

the radiator grille has been painted over and lacks an emblem;

the heater ventilator is half-blanked;

the front valances are odd - offside is a newer deep pattern,

while nearside is an original with blanked brake ventilator grille;

advertising frames are fitted.

MTLs's RMs on route 139 have now been displaced by new Marshall bodied Darts.

-

Advertising frames. Standard sized adverts were fitted to Routemasters for many years.

RM 1577 was fitted in 1963 with an internally-illuminated offside advertising panel.

As this was successful, RM 1923-2121 were built with such panels,

although they were latterly less popular

and sometimes acted as frames for ordinary adverts.

A new generation of vinyl adverts of varying sizes started to cause

problems with bodyside damage during removal,

and much of the fleet was fitted with frames.

RMs received an offside frame that covered the staircase area

as well as the between-decks.

There was also a nearside frame

and a small frame below the platform window.

- A spotlight was fitted to each new Routemaster,

tucked into a cut-out on the nearside valance.

The deeper RML valances had no cut-out, and pushed the spotlight down.

A recent trend has seen the removal of spotlights from buses in service

(probably due to regulation changes?).

Spot the differences

Differences under the skin

- Engines

The RMs with the most obvious non-visual difference were those with Leyland engines.

Leyland was invited to provide chassis units for Park Royal to install under RMs,

but the scale of production was too small to be worth Leyland's while.

They were busy by this time with the new Atlanteans.

But they could, and did, provide engines:

9.8 litre 0.600 diesel engines provided a throatier roar that announced their presence.

The roar was largely of air entering the engine,

which had been designed for use with an air filter that LT rejected.

RM632 was the first fitted, in 1961,

having its AEC engine removed at Leyland

for the purpose of engineering the fixings and fittings.

RM 871 had a Leyland engine from new, as did RM 1009.

The Leyland trio worked together from Hanwell (HW),

for monitoring purposes, until 1963,

when they went to Cricklewood (W).

Meanwhile RM 1255-RM1452 were Leyland fitted,

followed by RM 1521-1719 (ie not the RMCs),

then RM1811-1985.

Leyland buses tended to be clumped together to assist maintenance,

but not exclusively so.

Garages most associated with the Leyland buses were Mortlake (M),

Tottenham (AR), Cricklewood (W), Stockwell (SW), Upton Park (U),

Croydon (TC), Holloway (HT), Rye Lane (RL), Peckham (PM) and Barking (BK).

Although RMs with Leyland engines tended to re-emerge from overhaul

still with a Leyland engine,

they often did so with a different fleet number,

so gradually the Leyland buses permeated the number range.

They were phased out from the 1980s,

not because of any intrinsic weakness, but to reduce spares holding.

Oddly, the choice of engine did not affect the type code!

- Electrical systems

The RM was designed around an alternator-driven AC electrical system,

a novelty at that time.

However, the first twenty were given familiar DC dynamo systems

with heavier batteries.

These were RM5 - RM21, plus RM341, RM398 and RM459

(the last three from the test rigs).

Even within these twenty there were four different sets of equipment!

All were converted to AC within two years.

The AC sets were also of different, non-interchangeable types,

either from CAV or Simms, giving rise to a number of type codes.

The AC sets were also of different, non-interchangeable types,

either from CAV or Simms, giving rise to a number of type codes.

- Transmissions were by SCG or CAV,

the former being coupled with either CAV or Simms electrics:

more complications!

- Batteries Apart from the heavy duty batteries on the DC buses,

LT also experimented with alkaline batteries in place of lead-acid ones.

The alkaline batteries were fitted to RM22-RM121 (initially)

and remained associated with Poplar (PR) and West Ham (WH) Depots.

- Braking systems were of a continuous flow hydraulic system,

by Lockheed, except for RM 1055-RM 1154,

which had Clayton-Dewandre brake

Preserved RM1699 at North Weald rally, 1998.

- Suspension:

four types of air suspension

were tried out on early production buses:

RM75, RM87-105 had Firestone type 1 'Airide'

RM 106 - RM 110 had Firestone type 2 @Airide'

RM 111 - RM 130 had Dunlop 'Pneuride'

RM 131- RM 135 had Dunlop 'Dillow'

RM 76 - RM 308 all had conduit for the fitting of air suspension.

No further buses received it,

and the trial buses had their bags replaced by standard coil springs

when renewal was necessary. In some cases this was not until the 1980s.

Much later, in 1975, during the XRM project, RM1 was fitted with Lockheeds Active Ride Control system,

a hydraulic suspension system.

The thinking behind this was for kneeling buses to speed loading at stops

(yes, London Transport, 1975!)

Trials with RM1 were satisfactory enough for the equipment to be fitted (in 1978) to RM 116 for road testing,

on the busy route 9 through the City. RM 116 operated with it from 1980 until 1987.

As with the Advanced Passenger Train, the system worked perhaps too well on corners,

giving passengers a discrepancy between what their eyes and ears told them.

Next: Into service.

Photographic references are on a separate page.

So is the Fleet History.

Ian's Bus Stop

Ian's Bus Stop

RM Contents

RM Contents

RM8

RM8

RMs, pt1

RMs, pt1

RMs, pt2

RMs, pt2

|

This section is in several parts:

This section is in several parts:

Ian's Bus Stop

Ian's Bus Stop RM Contents

RM Contents RM8

RM8 RMs, pt1

RMs, pt1 RMs, pt2

RMs, pt2